Blown film manufacturing is the sole focus at Mid South Extrusion—and it has been since 1986. While other plastic film manufacturers branch into printing or fulfillment, MSE stays committed to one process: producing high-quality polyethylene film through blown film extrusion. This specialized approach ensures superior product performance, faster turnaround times, and more competitive pricing for our partners in the flexible packaging industry.

Why Do Plastic Film Manufacturers Stay Focused on One Process?

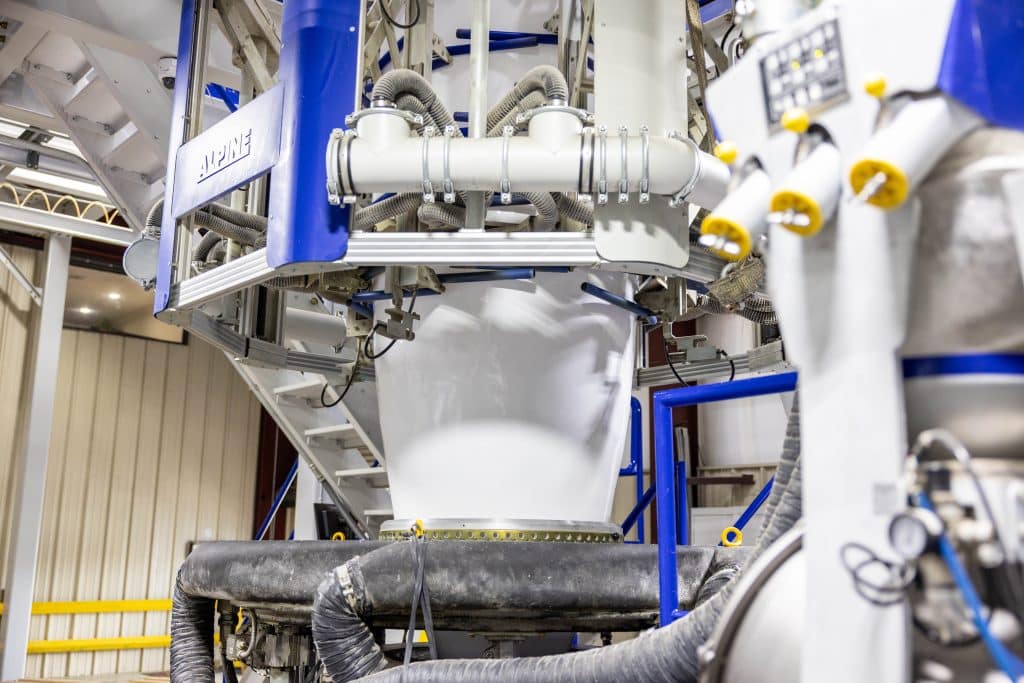

Mid South Extrusion (MSE) started producing blown film extrusion in Monroe, Louisiana, in 1986. For more than 39 years we have kept our eyes on that single target. Many plastic extrusion companies add printing, converting, or even product fulfillment. We prefer to invest every dollar in new facilities, state of the art equipment, and skilled operators. Because of that focus, customers receive higher quality film, dependable lead times, and competitive pricing.

What Does “Manufacturing Only” Mean for Plastic Extrusion Companies?

A flexible‑packaging supply chain usually moves from resin to film, then to converted packages, and finally to filling lines. Some firms try to own each stage. That path is called vertical integration. MSE chooses a different route. We buy prime polyethylene resin, run it through state‑of‑the‑art lines, and ship finished rolls to the converters and printers you already trust. This clear split keeps us efficient and keeps you in control of your downstream partners.

Why Does Skipping Vertical Integration Help Customers?

Faster innovation cycles

New ideas move from the lab to the line without waiting for printing schedules.

Lower overhead equals better pricing

We do not pay for presses, ink rooms, or distribution centers, so your invoice covers film only.

Deep technical expertise

Our engineers study gauges, additive packs, and layer blends daily. They dial in specs that hit targets the first time.

Flexible production scheduling

We manage only extrusion assets, so we can open capacity quickly when forecasts change.

Freedom to partner

You keep relationships with best‑in‑class converters and printers. We back them up with film that threads and seals without drama.

How Do Our Quality Systems Protect Your Film?

Every line runs statistical process control. Operators can pull samples every hour for lab testing. We track coefficient of friction, tensile strength, dart impact, and haze from start to finish. ISO‑style audits confirm the data. When a roll leaves our dock, you know it meets spec.

What Is Next for Blown Film Extrusion at MSE?

Focus never blocks innovation. Our R&D team now blends post‑consumer recycled (PCR) resin, tests bio‑based additives, and pushes downgauging to save material. Every improvement happens on the same Louisiana floor that produced our first roll. Focus and progress grow together.

Where Can You See Our Blown Film Extrusion in Action?

If you need reliable rolls from dedicated plastic film manufacturers, reach out today. We can send a sample roll or arrange a virtual plant tour. See how a manufacturing‑only model turns resin into results.

Frequently Asked Questions

What is vertical integration?

Vertical integration means one company owns several steps in the supply chain, such as extrusion, printing, and distribution.

Why does avoiding vertical integration lower my total cost?

Specialized plants carry less overhead and pass savings directly to you.

Does MSE outsource any part of production?

No. All blown film extrusion happens in Monroe, Louisiana.

How do you keep quality stable without owning downstream steps?

We track key metrics on every run and coordinate specs with your converters.

Can you support just‑in‑time programs?

Yes. Flexible scheduling and regional warehousing let you pull what you need when you need it.

How fast can you turn a custom blown film order?

Standard customs ship in seven to ten days. Expedited slots are available.

What certifications do your manufacturing lines carry?

Our facility meets SQF food‑safety requirements and follows ISO‑compliant procedures.

Do you collaborate with printers and converters we already use?

Absolutely. We supply film tailored to their equipment and share data to speed startups.

How does specialization help with sustainable film design?

A focused R&D team accelerates PCR projects and downgauging to cut resin use.

Where can I get a technical data sheet on your standard products?

Download data sheets at msefilms.com/resources or ask your account manager.